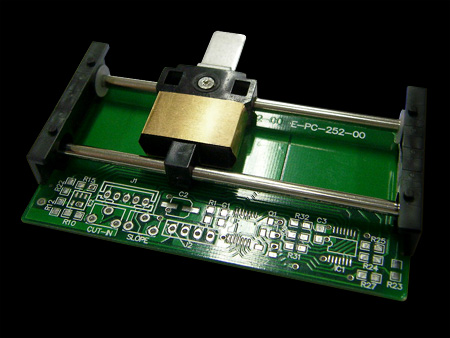

One of the biggest technological hurdles facing faders is contact. On a traditional VCA fader, the fader body runs along rails, but one side has to physically be in contact with carbon strips. This contact causes resistance to the touch as well as longer term wear, which in turn requires regular cleaning. The innoFADER however uses a unique capacitance based technology. The fader body glides on rails between 2 circuit boards which track the location and feed it back to the mixer digitally.

No contact means no bleed, which is when audio comes through even if the fader is closed - a classic problem for traditional VCA faders. This is caused by the grime from worn Carbon fader tracks as well as the gradual build up of daily DJ dirt interfering with the fader action. The innoFADER has no Carbon tracks to wear down or that can be effected by dirt which gives you 3 distinct benefits:

• The life of the innoFADER is vastly increased compared to conventional VCA technology

• Instead of very regular cleaning, only routine maintenance is needed to keep the rails running smoothly.

• A reduction in friction, leading to a smoother fader action.

So owning an innoFADER means no more fader brush cleaning, prolonged fader life and near guaranteed bleed-free smoother performance.